| RESEARCH & DEVELOPMENT |

|

-

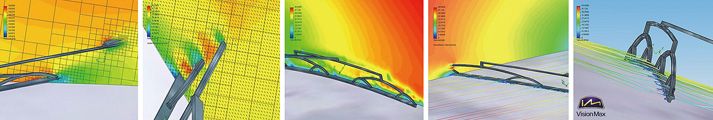

Engineering Capability

IMAX has technology center test laboratory and

20 employees. IMAX has pro/Engineer, IDEAS, Unigraphics

CATIA software to finish imitate wiping on the road. |

|

|

| |

-

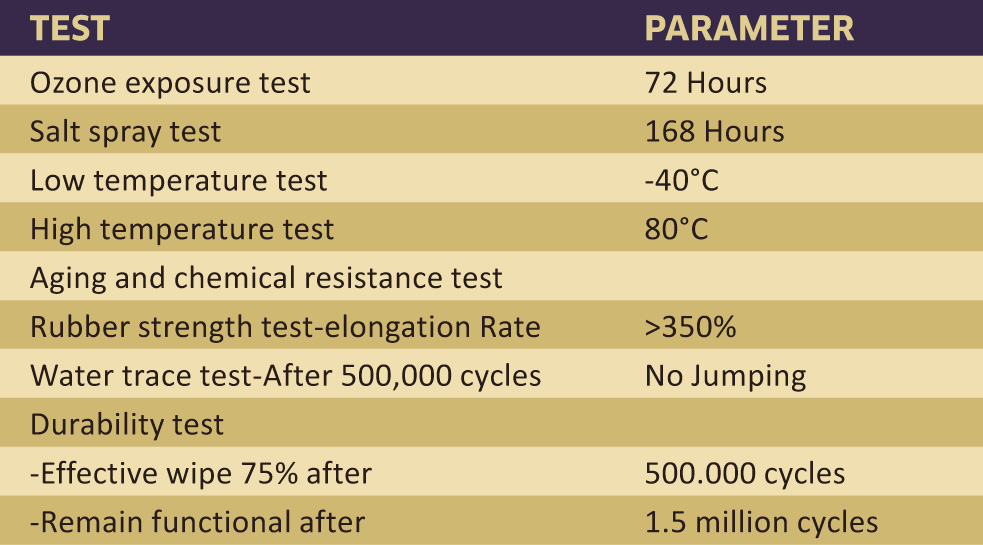

Technology and Test

IMAX provide professional technology test for wordwide

vehicles:

1, Reliability test. 2, Salt spray test. 3, Acoustics

test. 4, Mechanical test. 5, Paint hardness\Thickness\Tape

adhesion test. 6, Durability test. 7, High and low

rubber fission test. |

|

|

| |

-

Quality Management

Extremely demanding of ourselves with Germany advanced

technology.IMAX improve step by step. Annually reducing

costs; Increasing product performance and durability.

Improving customer satisfaction; and enhancing product

features are all worldwide objectives. And it takes

a world-class company such as products t IMAX o

offer these qualities.

IMAX extensive high quality wiper blade line

is supported by a totally integrated manufacturing

process. From quality rubber materials to the final

finished product. our manufacturing procedures include-stamping,

plastic injection electrical coating, powder painting

& final stringent testing. emulating the most

adverse conditions. |

|

|

| |

-

Production Line

IMAX has variety manufacturing equipments:

1, Flexible production line for small batch, production

runs.

2, Well-trained employees for different product

lines.

3, Preventive and predictive equipment maintenance

to reduce breakdown time.

4, MRP-based material control system to satisfy

production demand while controlling inventory.

5, FIFO management, space formula storage, saving

space, 24H uninterrupted service and fast response.

|

|

|

|

|

|